machining surface finish ra

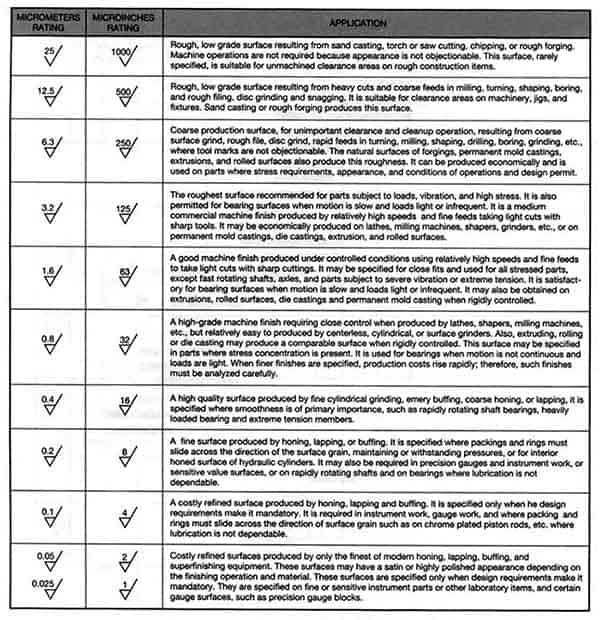

The value of surface roughness of the machined part is not. They range from 25 um to 0025 um and apply to all kinds of manufacturing and post-processing.

Surface Roughness Explained Get It Made

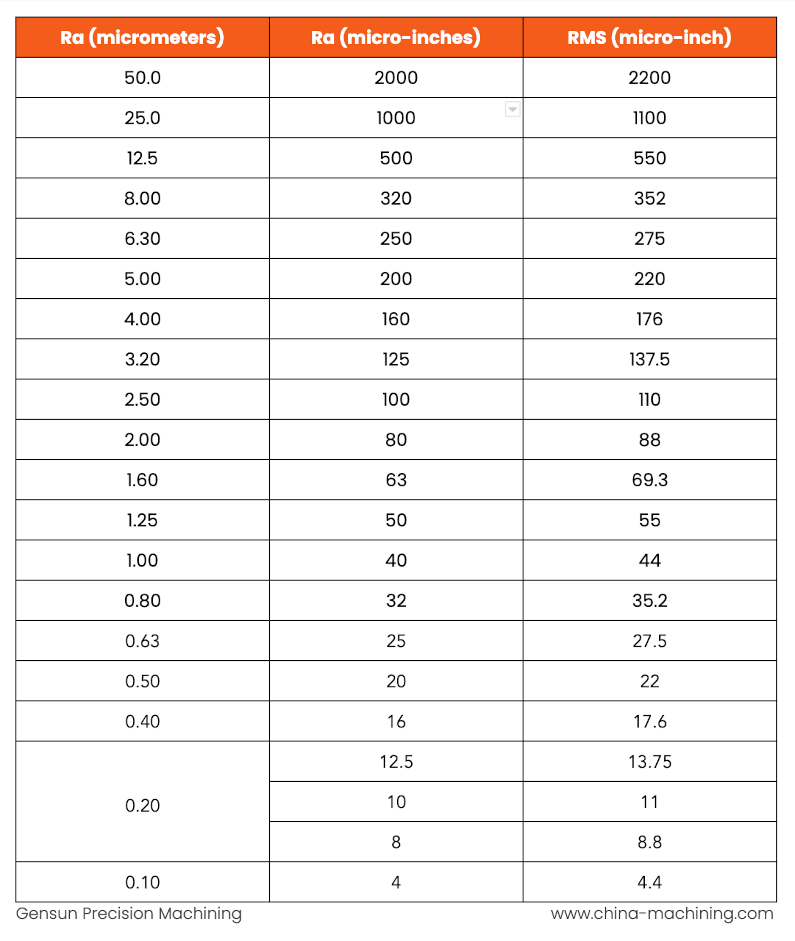

These are the values that may be specified during CNC machining.

. A components average roughness Ra is the difference between the actual machining and ideal machining surface roughness which can vary depending on the use case. Below are listed some of the Ra values. 32 μm Ra It is the typical finish for.

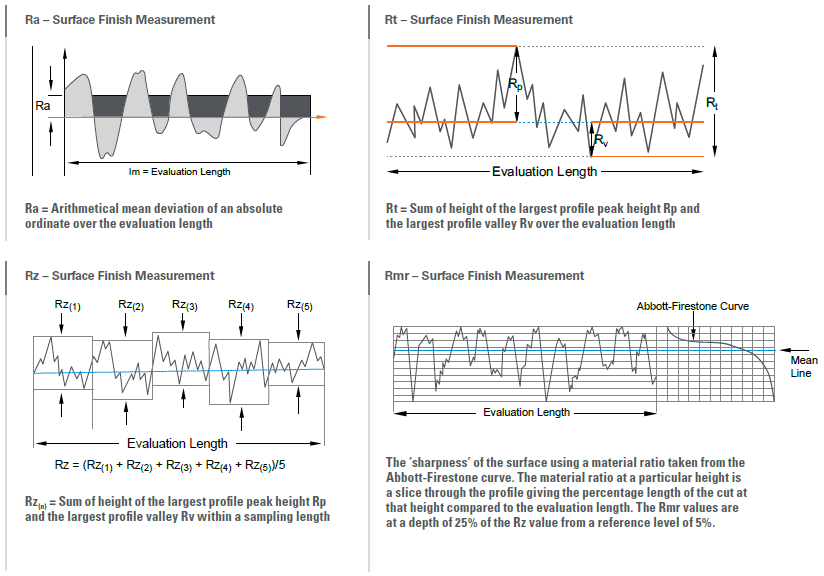

Surface finish is a parameter that determines the physical characteristics appearance of a component. The standard roughness for CNC machined parts is Ra 32 microns but you can do as fine as for example 02 microns on a CNC machine but it might take 10 times longer and. This is done by breaking the total measuring.

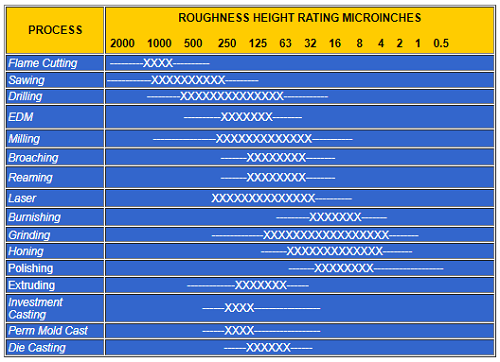

They are units used in measuring surface finish. This table will help you understand the impact of the machining process on the surface finish. The surface finishes smooth degree is an important requirement as for the machining to steel and iron castings.

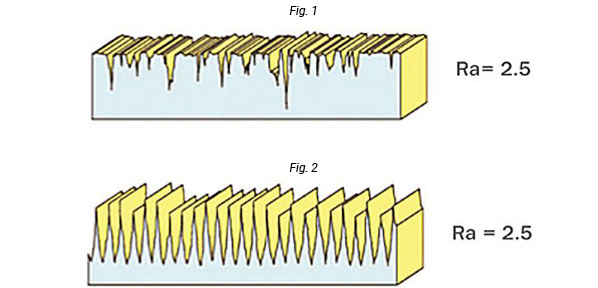

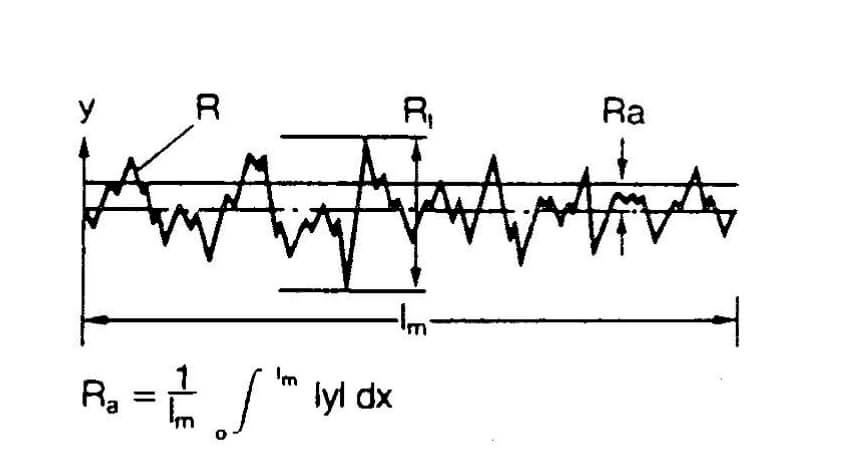

Ra Average Surface Roughness While most people refer to Ra as Center Line Average or Arithmetic Average it is the average roughness. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an. Ra Average Roughness.

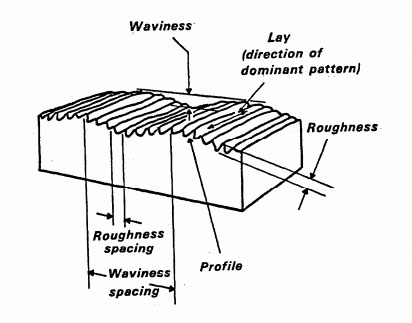

When measuring surface roughness the first step is to filter out the waviness component from the roughness component. Today Yide Casting will introduce the conversion in. The lower the Ra value the more machining effortoperations necessary hence quality control.

According to ASME B461 Ra is the. We will discuss below the typical surface roughness units in use in the machining world Ra Roughness Average Ra is the most commonly used unit. The value of surface roughness therefore is paramount and extra precaution should be taken while performing CNC machining.

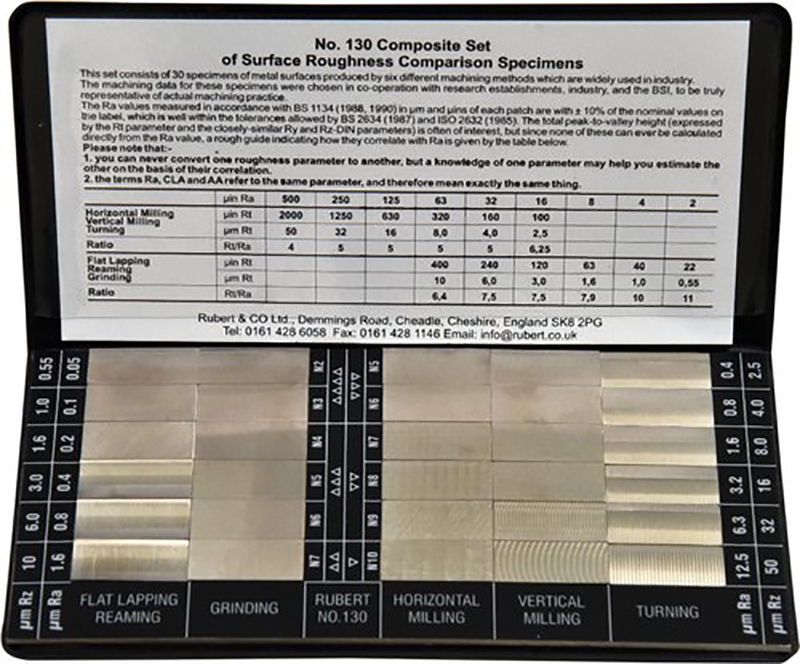

Surface Roughness Produced by Different Manufacturing Process. It is a means of altering material surfaces through processes involving adding. Indicative Surface Roughness Comparisons.

According to doctor blades manufacturer Swedevs website Ra is the arithmetical average value of all absolute distances of the roughness profile from the center line within the.

The Experimental Values Of The Roughness Of Surfaces Ra And Rz Download Table

Surface Roughness Finish Review And Equations

The Basics Of Surface Finish Gd T Basics

Surface Finish Chart An Precision Engineering

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Metrology For Manufacturing Surface Measurement

Average Roughness Basics Michigan Metrology

Surface Roughness Finish For Bearings And Seals Hallite

Surface Finish A Complete Guide To Surface Roughness Wayken

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Average Roughness Basics Michigan Metrology

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Beyond Ra Why Surface Finish Matters In Seal Performance Fluid Power Journal

How To Distinguish Cnc Machining Surface Roughness Between 6 3 And 0 8 Cnc Machining Pcbway

Surface Finish Cnc Turning Cnc Training Centre

Understand The Surface Roughness Chart And Make Great Parts

Surface Finish Quality Ra Rz Rt Surface Roughness Measuring Finish

So You Need A Good Surface Finish Youtube

Surface Roughness A Guide To Metal Additive Manufacturing By Digital Alloys Manufactur3d